Product Price :

$80,000.00-$95,000.00/setMix type :

Central mixWarranty :

12 MonthsPayment :

T/T,L/C,T/T & L/COrigin :

FUJIAN,CHINALead Time :

30 DAYSYHZS75 Mobile Central Mix Batch Plant designed in compact structure, the mixer can be folded before trailing, and can be move site to site easily.

The Feature of Mobile central mix batch plants:

Trailing unit

● Equipped turntable unit, easy to be pull away

● Double axle chassis, easy to move

● Equipped Hydraulic support legs, to make the plant stand stable during the operation

Aggregate batcher

● 4*5m3 aggregate hoppers

● Equipped TAIWAN AIRTAC air cylinder to control the discharge gate

● Equipped HK CHIMEI load cell, guarantee the weighing accuracy

● Equipped OLI vibrator to make sure smooth feeding.

● Each bins with top screen mesh to avoid oversize aggregate

Trough belt conveyor

● Up to 45 degree inclination, stand small area

● Equipped with pulling switch for emergency stop

● Equipped with spiral roller and alloy cleaner to clean the belt

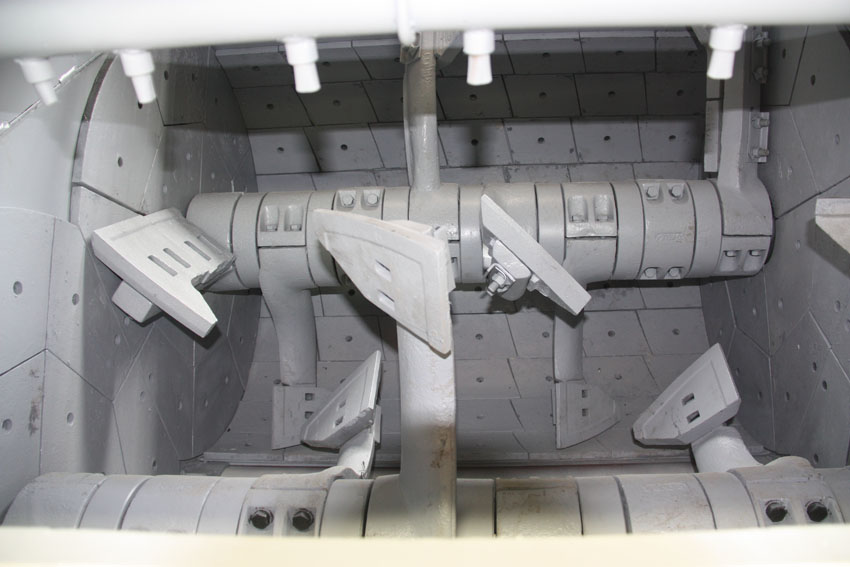

Mixing system

● Twin-shaft compulsory mixer

● Heavy duty design and multi seal protection

● Equipped wear-resistant alloy blade and lining tile(changeable), thecontinuously mixing can up to 160,000 times

● Equipped with auto lubricate pump

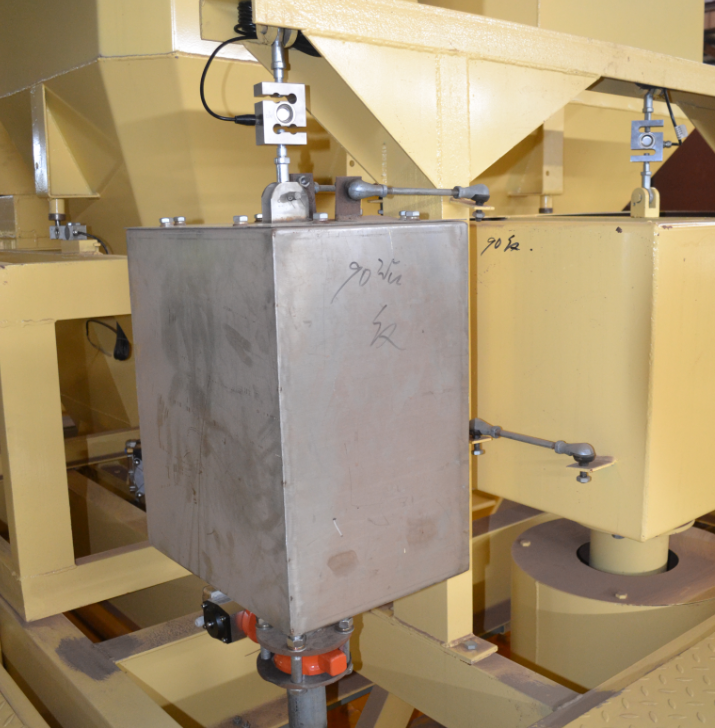

Cement and fly ash weighing

● Adopting air vibrating system, vibrating evenly and better to protect the hopper

● Equipped SICOMA pneumatic butterfly valve

● Reasonable permeability design can balance the pressure during filling.

Water and additive weighing

● Equipped with stainless steel tank and pump for additive to against rust and corrosion

● Equipped with Electro-pneumatically operated butterfly valve

Pneumatic system

● Equipped with TAIWAN FUSHENG air compressor

● Adopting TAIWAN AIR TAC air cylinders, valves, hoses, filters and other fittings

Intelligent computer control system

● Fully automatic and manual operation of the system is possible

● All cable /wire with tracking code to provide easy maintenance

● Adopting SIENMENS or SCHNEIDER relay, button, air breaker and contactor

● Flexible production with lots of parameters.

● Records for every batch separately.

On site service of Movable batching plants:

We will dispatch 1 technician to your place to guide the installation, testing and training your operator. Buyer to pay for round air ticket, board (meals), lodging expenses and a daily allowance of USD$100 per person per day for our service engineer.

Normally it will take 10-15 working days to finish the installation and commissioning of the small movable batching plants.

|

Model |

YHZS75 |

|

Theoretical production(m3/hr) |

75 |

|

Aggregate hopper qty |

2/4 |

|

Aggregate hopper capacity(m3) |

15/7.5 |

|

Aggregate weighing capability (kg) |

3500 |

|

Slant belt conveyor |

Trough belt |

|

Cement weighing capability (kg) |

900 |

|

Water weighing capability (kg) |

500 |

|

Additive weighing capability (kg) |

30 |

|

Mixer model |

MSO2250 |

|

Mixer capacity (M3) |

1.5 |

|

Mixing type |

Twin shaft |

|

Mixing cycle (s) |

72 |

|

Control system |

Intelligent controlling (IPC+INSTRUMENT) |

|

Discharge height (M) |

≧2.8 |

|

Trailing speed (km/hr) |

15 |

|

Total power (kw)(without optional parts) |

≈98 |

|

Total weight(T)(without optional parts) |

27 |

|

Transportation conditions |

2*40HQ Container |

Previous:

Foundation free mobile concrete batching plantNext:

YHZS-50 Small Mobile Concrete Batching Plant for saleAddress: Wanrong Road, Luojiang Area, Quanzhou, Fujian, China

Tel: 0086-18965721886;

Fax: 0086-595-22428460

newsletter

newsletter

Phone :

+86-18965721886Email :

wongzx@suntsing.comAddress :

Wanrong Road, Luojiang Area, Quanzhou, Fujian, ChinaSkype :

rambo-huangFriendly Links:

Copyright © Suntsing Construction Machinery Co.,Ltd..All Rights Reserved. Powered by dyyseo.com