Product Price :

$118,000.00/setMix type :

Central mixWarranty :

12 monthsPayment :

T/T,L/C,T/T & L/COrigin :

FUJIAN,CHINALead Time :

35 DAYSHZS-100 Stationary Cement Concrete Batching Plant, modular design, can be errected and relocated easily. With the capacity of 2 cubic meter per batch, can equipped with 6,8,10m3 mixing trucks

The main feature of HZS-100 Stationary Concrete Batching Plant:

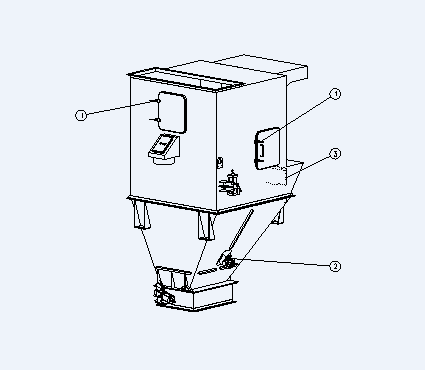

Aggregate batcher

● Suitable for storage 3-4 different types aggregate

● Equipped TAIWAN AIRTAC air cylinder to control the discharge gate

● Equipped HK CHIMEI load cell, guarantee the weighing accuracy

● Equipped OLI vibrator to make sure smooth feeding.

● Each bins with top screen mesh to avoid oversize aggregate

● Inside vibrating design available

Trough belt conveyor

● Up to 45 degree inclination, stand small area

● Equipped with pulling switch for emergency stop

● Equipped with spiral roller and alloy cleaner to clean the belt

● Rain cover available to reduce the dust emission and protect the belt

Aggregate Transit hopper

To make sure the continuous production , when the 1st batch mixing , the 2nd batch weighing at the same time, more efficiency and high production.

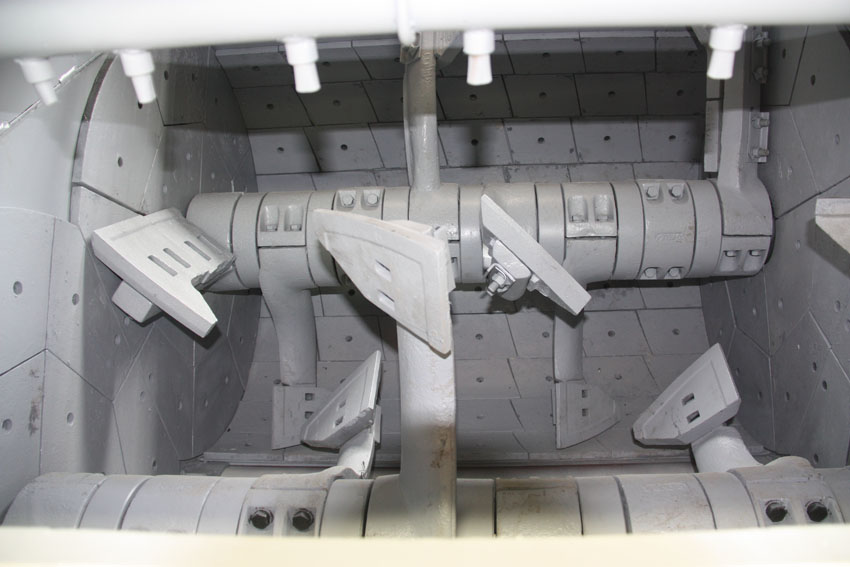

Mixing system

● Twin-shaft compulsory mixer

● Heavy duty design and multi seal protection

● Equipped wear-resistant alloy blade and lining tile(changeable), the continuously mixing can up to 160,000 times

● With maintenance and observing gate

● Equipped with auto lubricate pump

Cement and fly ash weighing

● Adopting air vibrating system, vibrating evenly and better to protect the hopper

● 3 nos load cells to guarantee the weighing precision

● Equipped SICOMA pneumatic butterfly valve

● Reasonable permeability design can balance the pressure during filling.

Water and additive weighing

● Rough and precise weighing design to ensure the measurement accuracy

● Equipped with stainless steel tank and pump for additive to against rust and corrosion

● Equipped with Electro-pneumatically operated butterfly valve

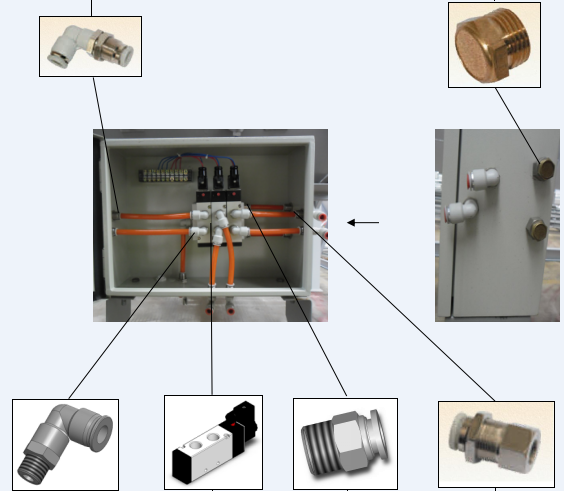

Pneumatic system

● Equipped with TAIWAN FUSHENG air compressor

● Adopting TAIWAN AIR TAC air cylinders, valves, hoses, filters and other fittings

● Equipped with small air bag for aggregate batcher to guarantee the enough pressure

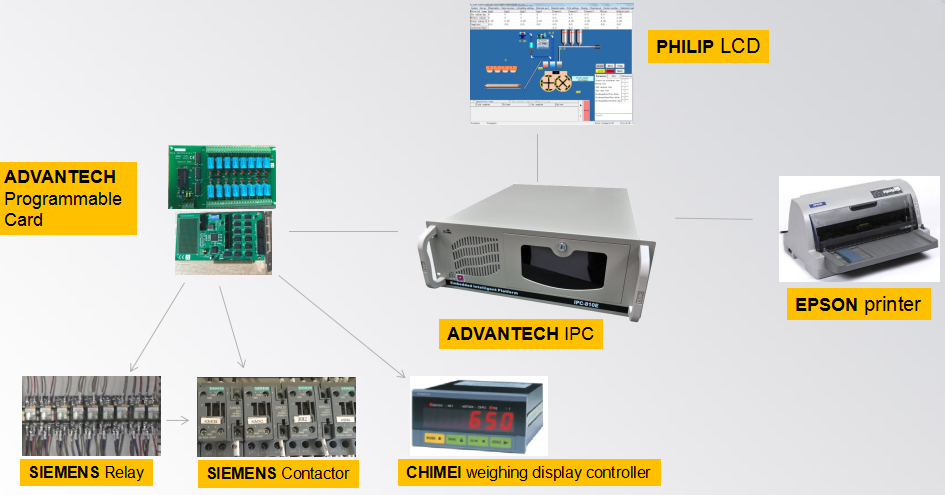

Intelligent computer control system

● Fully automatic and manual operation of the system is possible

● All cable /wire with tracking code to provide easy maintenance

● HK CHIMEI weighing indicators are equipped on control panels

● Adopting SIENMENS or SCHNEIDER relay, button, air breaker and contactor

● Full automatic concrete productions on computer inventory entry and inventory reports

● Flexible production with lots of parameters.

● Records for every batch separately.

Processing flow of HZS-100 Stationary concrete batching plant:

Design – raw material preparing and handling (sand blast and anti-corrosion painting) – cutting &welding –polishing – assemble – function test – top painting, and QC will supervise the whole processing flow. Normally it will take 20-25 working days to finish complete set of 100 m3 stationary batching plant.

Packing and container loading of cement concrete batching plant:

Model

HZS-35

HZS-50

HZS-75

HZS-100

HZS-150

50T silo

100T silo

200T silo

Container

2*40HQ

3*40HQ

4*40HQ

4*40HQ

4*40HQ+1*40OT

1*20GP

1*40HQ

1*40HQ

On site service of on site batching plant:

We will dispatch 1 technician to your place to guide the installation, testing and training your operator. Buyer to pay for round air ticket, board (meals), lodging expenses and a daily allowance of USD$100 per person per day for our service engineer.

Normally it will take 15-20 working days to finish the installation and commissioning of 100 m3 stationary concrete batching plant.

|

Model |

HZS100 |

|

Theoretical production(m3/hr) |

100 |

|

Aggregate hopper qty |

3-5 |

|

Aggregate hopper capacity(m3) |

18 |

|

Aggregate weighing capability (kg) |

4500 |

|

Slant belt conveyor |

Trough belt |

|

Belt conveyor capability (t/hr) |

400 |

|

Cement weighing capability (kg) |

1200 |

|

Fly ash weighing capability(kg) |

400 |

|

Water weighing capability (kg) |

600 |

|

Additive weighing capability (kg) |

30 |

|

Mixer model |

MAO3000 |

|

Mixer capacity (M3) |

2 |

|

Mixing type |

Twin shaft |

|

Mixing cycle (s) |

72/60 |

|

Control system |

Intelligent controlling (IPC+INSTRUMENT) |

|

Discharge height (M) |

≧4.0 |

|

Total power (kw)(without optional parts) |

≈118 |

|

Total weight(T)(without optional parts) |

47 |

|

Transportation conditions |

4*40HQ Container |

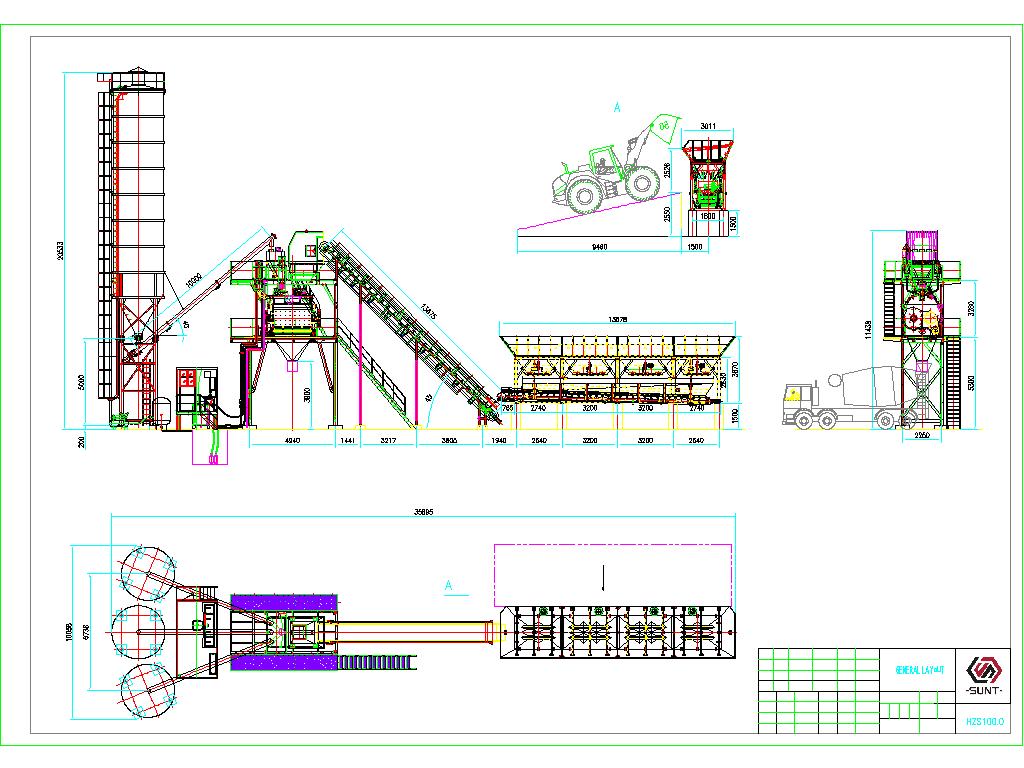

The layout of HZS-100 Cement Concrete Batching Plant:

Address: Wanrong Road, Luojiang Area, Quanzhou, Fujian, China

Tel: 0086-18965721886;

Fax: 0086-595-22428460

newsletter

newsletter

Phone :

+86-18965721886Email :

wongzx@suntsing.comAddress :

Wanrong Road, Luojiang Area, Quanzhou, Fujian, ChinaSkype :

rambo-huangFriendly Links:

Copyright © Suntsing Construction Machinery Co.,Ltd..All Rights Reserved. Powered by dyyseo.com