Product Price :

$198,500.00-$220,600.00/setMix type :

Central mixWarranty :

12 monthsPayment :

T/T,L/C,T/T & L/COrigin :

FUJIAN,CHINALead Time :

45 DAYSHZS-240 Stationary Ready Mixed Concrete Mixing Station equipped with dust removal, external packing, and two computer control system to guarantee the non-stop production, it's an ideal model for large precast concrete factory, and large infrastructure projects, like big power station, sea port, air port and so on.

The feature of HZS-240 Stationary Ready mixed concrete mixing station:

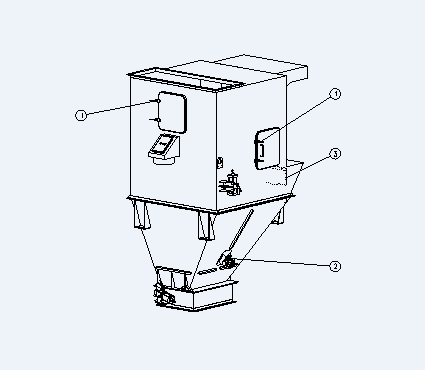

Aggregate batcher

● Each weighing system works independently at the same time.

● Equipped TAIWAN AIRTAC air cylinder to control the discharge gate

● Equipped HK CHIMEI load cell, guarantee the weighing accuracy

● Each bins with top screen mesh to avoid oversize aggregate.

● Inside vibrating design, feeding fast and damage free on outside hopper board.

Plain belt conveyor

● 20 degree inclination, feeding stable and easy to clean the belt.

● Equipped with tensioner, to avoid deviation.

● Equipped with pulling switch for emergency stop

● Double side aisle, easy to do maintenance and safety

● Equipped Rain cover to reduce the dust emission and protect the belt

Aggregate Transit hopper

To make sure the continuous production , when the 1st batch mixing , the 2nd batch weighing at the same time, more efficiency and high production.

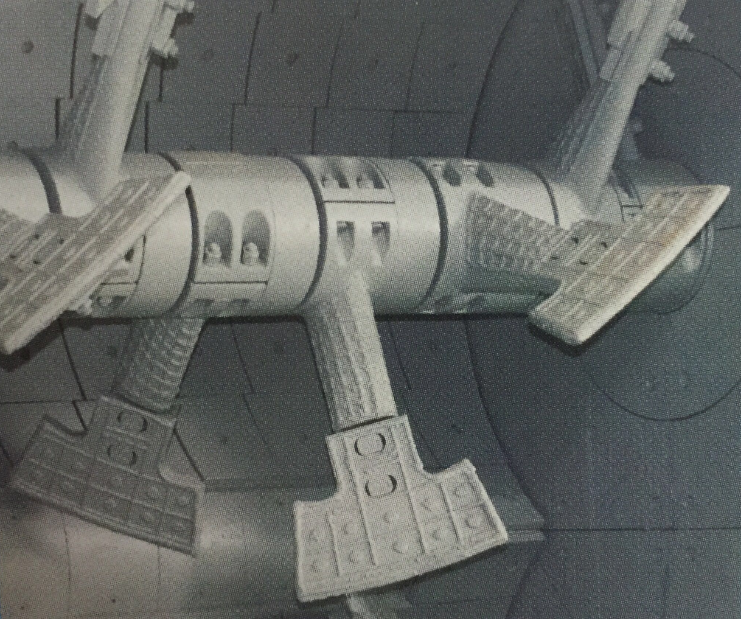

Mixing system

● Heavy duty design,stable operation

● Shaft ends multi seal protection and air purge seal protection to efficiently prevent leakage.

● Equipped wear-resistant alloy blade and lining tile(changeable), the continuously mixing can up to 160,000 times

● Multi-pipe water spraying to ensure even water distribution.

● Equipped with auto grease pump

Cement and fly ash weighing

● Adopting air vibrating system, vibrating evenly and better to protect the hopper

● 3 load cell to guarantee the weighing precision

● Equipped SICOMA pneumatic butterfly valve

● Reasonable permeability design can balance the pressure during filling.

Water and additive weighing

● Rough and precise weighing design to ensure the measurement accuracy

● Equipped with stainless steel tank and pump for additive to against rust and corrosion

● Equipped with Electro-pneumatically operated butterfly valve

Pneumatic system

● Equipped with TAIWAN FUSHENG air compressor

● Adopting TAIWAN AIR TAC air cylinders, valves, hoses, filters and other fittings

● Equipped with small air bag for aggregate batcher and mixing tower to guarantee the enough pressure

Intelligent computer control system

● Wide view control room

● Double control system Fully automatic and manual operation, in English.

● All wires & cables are coded, easy to track and maintenance

● Adopting SIENMENS or SCHNEIDER relay, button, air breaker and contactor

● Easy to set and file the production formula list.

● Easy to check the records and details

● Permission limited to change the parameter

Environment protection system

● Equipped 24m2 impulse dust filter, collection efficiency up to 99.8%. Auto clean and reuse the dust, low maintenance cost.

● External packing for mixing tower, looks beautiful, reduce the dust and noise emission

Processing flow of RMC Batching Plants:

Design – raw material preparing and handling (sand blast and anti-corrosion painting) – cutting &welding –polishing – assemble – function test – top painting, and QC will supervise the whole processing flow. Normally it will take 30-35 working days to finish complete set of HZS-240 RMC batching plants

Packing and container loading of Stationary Ready mixed concrete mixing station:

| Model | HZS-90 | HZS-120 | HZS-180 | HZS-240 | 100T silo | 200T silo | 300T silo |

| Container loading |

5*40HQ |

4*40HQ+1*40OT |

5*40HQ+1*40OT |

5*40HQ+1*40OT+1*20FR |

1*40HQ | 1*40HQ | 1*40HQ+1*20GP |

On site service of HZS-240 RMC batching plants:

We will dispatch 2 technicians to your place to guide the installation, testing and training your operator. Buyer to pay for round air ticket, board (meals), lodging expenses and a daily allowance of USD$100 per person per day for our service engineer.

Normally it will take 20-25 working days to finish the installation and commissioning of 240m3/hr Stationary concrete mixing stations.

|

Model |

HZS240 |

|

Theoretical production(m3/hr) |

240 |

|

Aggregate hopper qty |

4-6 |

|

Aggregate hopper capacity(m3) |

50 |

|

Aggregate weighing capability (kg) |

9000 |

|

Slant belt conveyor |

Plane belt |

|

Belt conveyor capability (t/hr) |

800 |

|

Cement weighing capability (kg) |

2400 |

|

Fly ash weighing capability(kg) |

800 |

|

Water weighing capability (kg) |

1000 |

|

Additive weighing capability (kg) |

100 |

|

Mixer model |

MAO6000 |

|

Mixer capacity (M3) |

4 |

|

Mixing type |

Twin shaft |

|

Mixing cycle (s) |

60 |

|

Control system |

Intelligent controlling (IPC+INSTRUMENT) |

|

Discharge height (M) |

≧4.2 |

|

Total power (kw)(without optional parts) |

≈237 |

|

Total weight(T)(without optional parts) |

68 |

|

Transportation conditions |

5*40HQ + 1*40OT+ 1*20 FR Container |

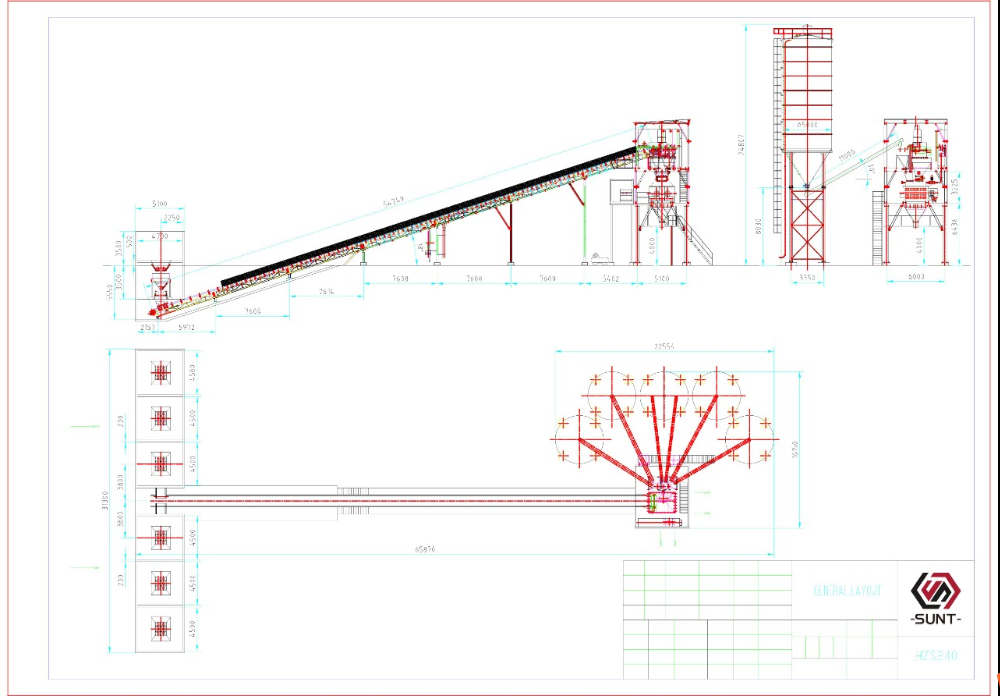

The layout of HZS-240 Stationary Ready mixed concrete mixing station:

Hot Tags :

Address: Wanrong Road, Luojiang Area, Quanzhou, Fujian, China

Tel: 0086-18965721886;

Fax: 0086-595-22428460

newsletter

newsletter

Phone :

+86-18965721886Email :

wongzx@suntsing.comAddress :

Wanrong Road, Luojiang Area, Quanzhou, Fujian, ChinaSkype :

rambo-huangFriendly Links:

Copyright © Suntsing Construction Machinery Co.,Ltd..All Rights Reserved. Powered by dyyseo.com