The advantages Of Twin-shafts compulsory concrete mixer

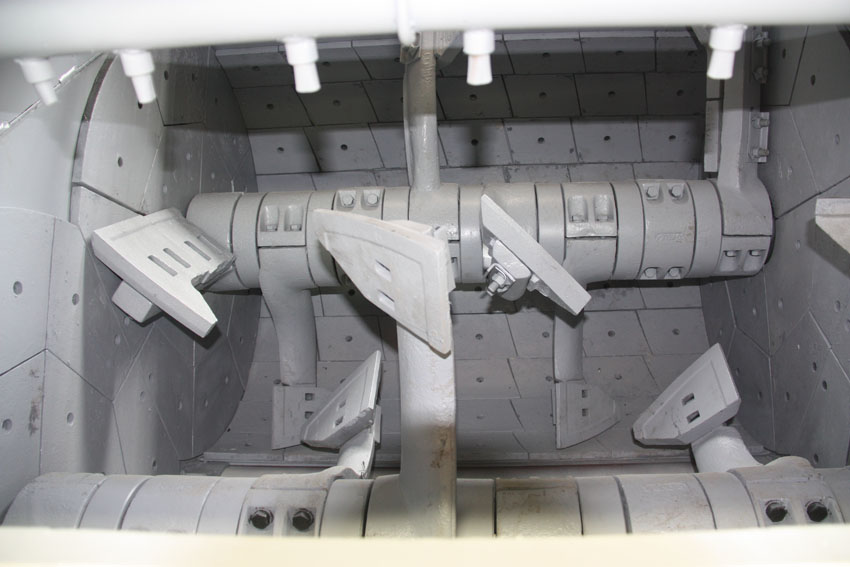

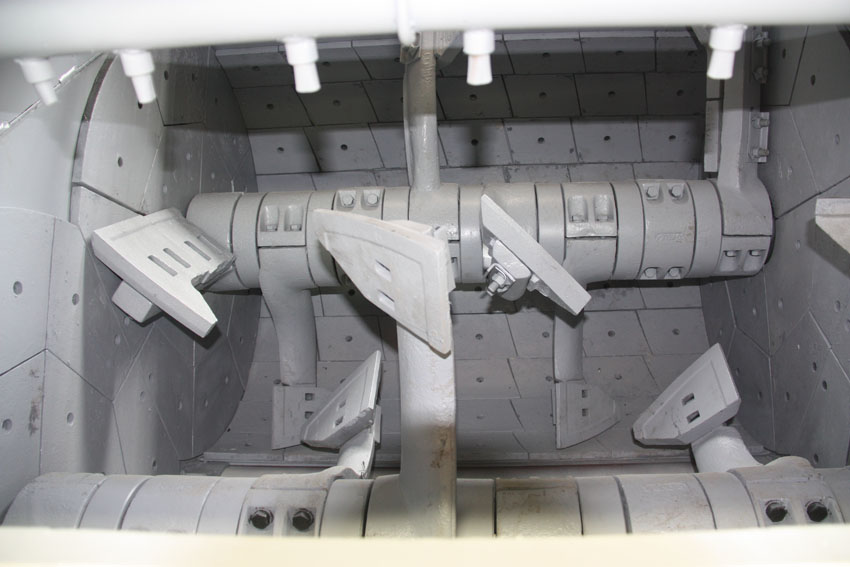

SICOMA twin-shaft concrete mixer, with sufficient rigidity and strength to ensure strong mixing capacity, stirring evenly and quickly. It achieves good mixing effect for all kinds of concrete, like dry mixing concrete, semi-dry mixing concrete and wet mixing concrete. The designed multi-angle mixer mixing arms can avoid the phenomenon of concrete sticking on the shafts. When the motors working the mixing shafts are counter rotation. The mixing blades make the materials remain on boiling motion. Meanwhile, under the action of shearing force from mixer mixing arm, the materials are mixed fully in a short time. The unique shape of the mixer mixing arms also participates in the mixing operation, thus greatly reducing the mixing time.

The mixer mixing blades can be adjusted easily on the direction of wearing force, until it must be replaced. The mixer mixing blades are made by high wear-resistant alloyed material. The life time can up to 100,000 batches.

The mixer lining boards of twin-shaft compulsory concrete mixer is made of high-chromium wear-resist cast iron. The normal life time will be more than 100,000 batches

The deceleration system of twin-shaft concrete mixer is the closed planetary reduction mode with flywheel end synchronization. It is compact structure, high transmission efficiency,easy maintenance and long life time. It can meet the mixing requirement of different slump concrete production.

The shaft end sealing parts: the shaft end supporting structure and sealing structure separation, so as to prevent sealing device malfunction in case the bearing damage. And MAO series mixer with advanced pneumatic sealing device.

The lubrication system of twin-shaft concrete mixer adopts the most advanced automatic grease filling system. The grease is supplied to different greasing point along the pipeline respectively. The grease into all greasing points and sealing chamber plays the role of lubrication sealing. The computer-controlled Intermittent grease injection mode ensures the minimum grease consumption while the shaft end sealing runs reliably.

newsletter

newsletter